Within the smartphone trade, there are just a handful of smartphone manufacturers that experience their very own chip. Smartly, by means of chip, we’re speaking concerning the smartphone processor and no longer a video chip, symbol, or charging optimization chips. Best Apple, Huawei, and Samsung are in line with their chips. Different producers like Xiaomi have smartphone chips, however they’re rarely constant. A couple of weeks in the past, Oppo launched its flagship smartphone Oppo In finding X5 Professional and it comes with its new chip, MariSilicon X. Alternatively, that is an unbiased symbol chip. Even the Xiaomi Surge S1 which is a cell phone chip does no longer have a successor after a few years.

It’s a lot more uncomplicated to supply a single-function chip like a picture chip. Those chips paintings with the processor to lend a hand optimize the picture efficiency. Right now, all manufacturers need to have a picture chip. Additionally, the highest manufacturers will ultimately need to have their very own smartphone processor. Nonetheless, there’s a fact that they’ve to simply accept. The processor isn’t one thing that may be carried out by means of simply fascinated by it. No longer simplest is it tricky to do, however it additionally burns cash.

Allow us to now check out some the reason why smartphone manufacturers can’t simply make processors.

1. Processors are complicated

These days’s processors aren’t such a lot single-function processors however are most commonly a whole system-on-chip. Let’s take the Apple A15 processor for instance. Along with the processor (CPU), there’s a graphics card (GPU), DSP, symbol processor (ISP), wi-fi baseband, AI processor (NPU), video Formats, components caches, and extra. The design of every phase isn’t easy, let’s take the baseband for instance.

Apple has been shouting concerning the closed-loop ecology for a few years, and the M1 processor has been rubbed out. Alternatively, it simply can’t get a operating 5G verbal exchange baseband. After biting the bullet and the use of Intel’s baseband for 2 years, it in the end needed to re-cooperate with Qualcomm. Because of this now we have Qualomm’s baseband within the iPhone.

Design is simply a side

And ah, the power to design those useful modules is just one facet. Producers even have so that you can mix those useful modules in combination. Mix purposes…Seems like construction blocks, proper? No longer so easy bro, there are lots of “How To’s” that may want solutions. One of the vital How To’s are The way to…

- attach those portions to one another

- make tradeoffs between energy intake and function

- select the fitting information trail

- make the {hardware} format and tool design appropriate

- successfully regulate leakage beneath nanotechnology and scale back static energy intake

- use the brand new etching era to optimize the method

- take care of the aggressive chance/noise interference beneath the high-speed sign

This construction block is tricky proper?. Can any producer remedy those issues? Sure, however no longer a lot will also be carried out. Apple, Huawei, and Samsung, all have their solutions however no longer with out cooperating with different firms.

Huawei has been operating onerous on chips since 2009. After just about ten years of study and building, it has invested loads of billions of bucks to in the end be capable of compete. Alternatively, the U.S. ban is hitting the corporate as it wishes sure American applied sciences to make the chips.

2. Processor manufacturing is scaringly dear

In fact, many smartphone manufacturers that need to input the chip marketplace aren’t even on the stage of designing the processor. It’s because when the crew format the technical necessities, the whole thing comes again to the start-up capital.

Let’s take a look at the simple phase. If a emblem desires to start out chip manufacturing, it cants simply pull a couple of other folks in a storage and phone it a crew. To make a chip, if the crew is not up to 100 other folks, it appears like a kid’s play. The wage of this crew on my own is some huge cash…

Along with human assets, the processors on our cell phones additionally wish to pay ARM. They’ve to pay ARM the related licensing charges for the acquisition of the ARM structure and IP cores.

Along with the above “see the tip” prices, there are some “no finish” prices which might be much more being worried.

You should know that insects will inevitably seem after a program is written. At the moment, programmers need to many times fine-tune the code and battle towards insects.

The similar is right of chip design – a chip design can’t be shaped in a single move. Because the design proceeds, it is going to go through a large number of middleman useful exams.

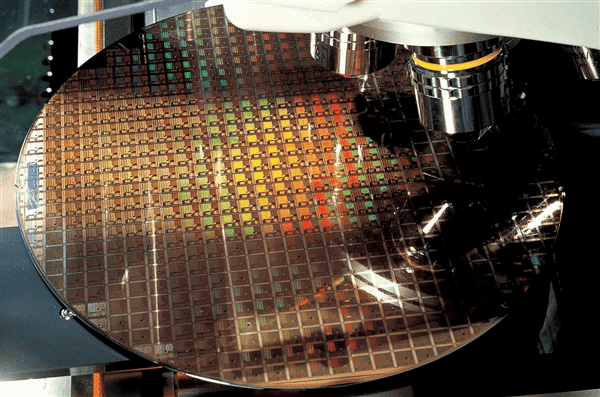

Some useful exams will also be carried out by means of tool simulating the running mode of the chip. Such exams are referred to as “emulation”. For different useful exams, some chips should be trial-produced in small batches and operated on an actual smartphone.

This procedure is named “tape out” and the trial manufacturing is clearly no longer unfastened. Within the 14nm procedure, the price of a tape-out is in tens of millions. Underneath the preferred 5nm procedure in 2021, the cost of a tape-out is round $50 million.

How a lot does it value to design a cell phone processor?

So, what number of tape-outs will you wish to have to make a chip? It’s unattainable to mention and this is without doubt one of the horrifying “no finish” prices. There can also be some insects that aren’t absolutely understood. This type of debugging tape-out is going from side to side a number of instances.

So in all of those, you’ll be questioning how a lot it is going to value to make a smartphone processor. Let’s take an instance…Huawei HiSilicon Kirin has invested 480 billion yuan ($75.5 billion) prior to now 10 years. Its investments in 2019 hit 131.7 billion yuan ($20.7 billion). It took a large number of effort to finish the Kirin collection SoC that may fit Apple’s Qualcomm.

3. A small growth calls for an enormous R&D

There are a couple of processes that apply the manufacturing of a smartphone processor. The irony of the method is which you can want other groups for various facets of the chip. Moreover, months and tens of millions of bucks would possibly disappear prior to you notice small growth. Smartphone manufacturers that don’t have the endurance, don’t move into chip manufacturing. For instance, the pop-up digicam, under-screen digicam, on-screen fingerprint sensors, and different new options all paintings with the processor. Simply to make an on-screen fingerprint sensor paintings, you might want a complete crew to paintings at the chip for a number of months.

Conclusion

Taking into consideration the hustle and bustle in addition to the large monetary dedication, many smartphone manufacturers simply focal point on their smartphones. They are going to choose to buy chips from “chip firms” akin to Qualcomm or MediaTek than making their very own interior chips.