Mining is without doubt one of the oldest industries in the market, nevertheless it has an increasing number of embraced high-tech strategies as call for has larger. Plotlogic makes use of hyperspectral imaging, a method typically present in labs and satellites, so as to add a brand new layer of knowledge and automation to those the most important however incessantly dated operations.

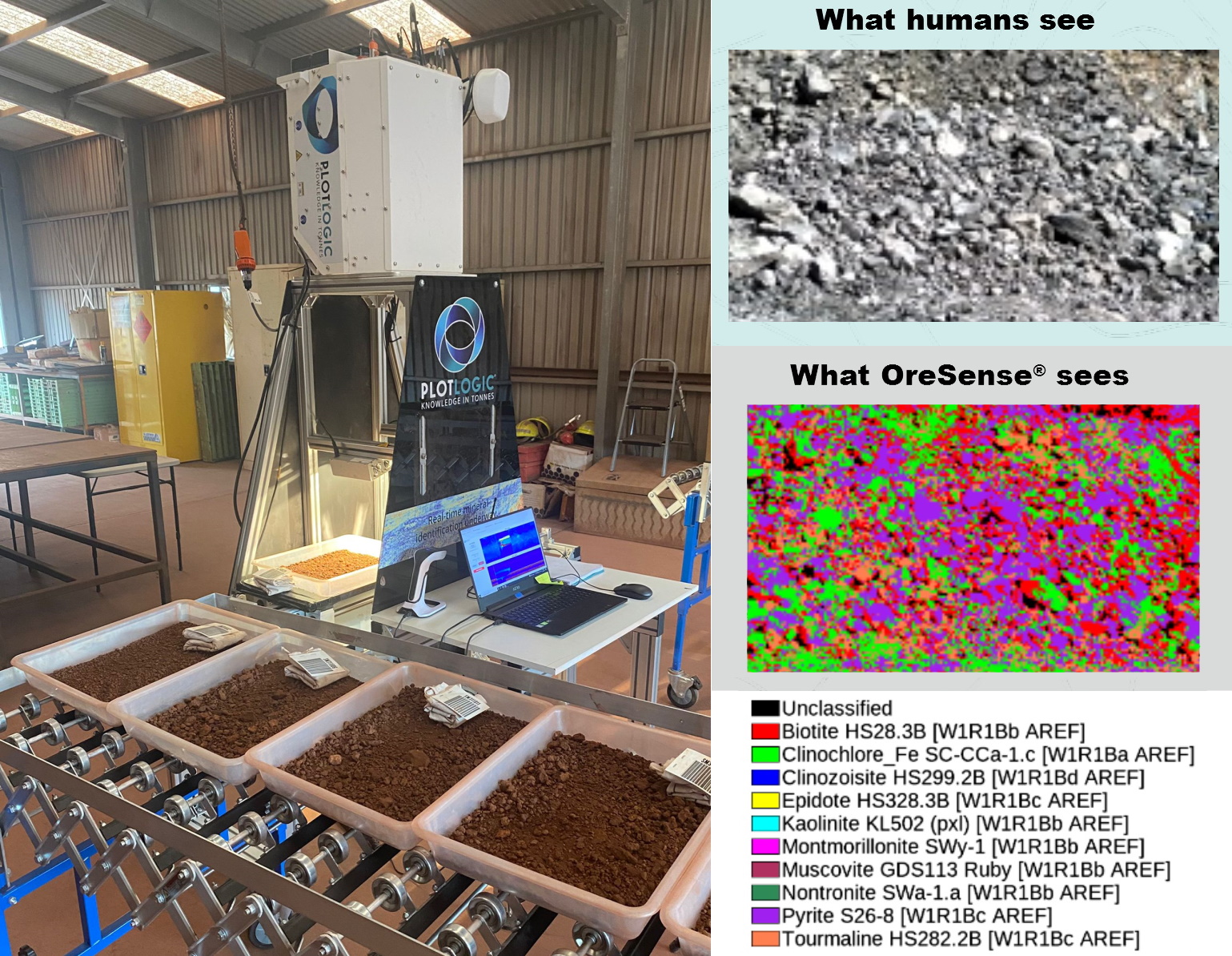

Hyperspectral imagery is principally a photograph that captures mild outdoor the visual vary, permitting differentiation of drugs that glance the similar to human eyes. As with just about the whole lot else, nature were given there first: birds and bugs can see wavelengths we will be able to’t, for a get started, and it adjustments their whole view of the sector.

We’ve followed the theory in a number of instances: It’s in the end a type of spectral research, the place you jump radiation off an object and spot what’s mirrored or absorbed. Each substance has its personal spectral signature, from pores and skin to cement to uncommon earth minerals. The latter class is clearly the place Plotlogic is aiming.

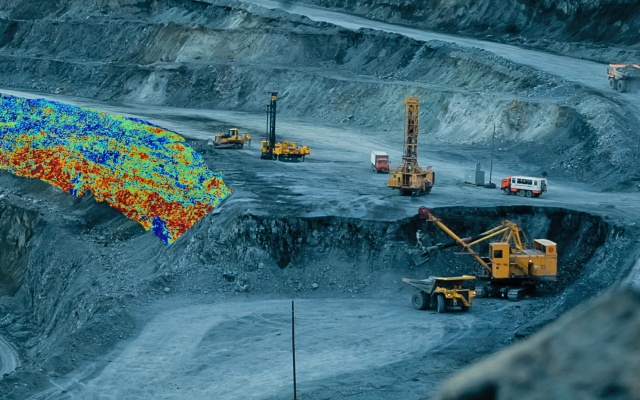

Based in 2018 in Brisbane, Australia, Plotlogic makes a multispectral-plus-lidar imaging setup that appears at a pile of rubble extracted from a mine and says, “there’s some lithium, there’s slightly of silver, there’s some sulfur.” (Despite the fact that I severely doubt the ones 3 might be present in the similar pile.)

In fact mines already do this kind of research someday. Another way how would they know what to refine, truck out and so forth? However this typically is dependent upon taking samples to a lab and filing them to — you guessed it — spectral research. Plotlogic is letting this the most important step happen on website online, doubtlessly making operations a lot more environment friendly.

A desk bound OreSense system scanning ore samples, and an instance of the way the ones samples may well be analyzed. Symbol Credit: Plotlogic

“That’s the true innovation right here: embedding it into mining operations and empowering mine group of workers with actual time knowledge,” mentioned CEO and founder Andrew Activity.

The corporate first deployed its OreSense machines in 2019, and has been iterating at the product since, with comments from primary mining corporations. It may be desk bound or cell, both scanning ore because it is going previous on a conveyor belt or going to the place it’s been gathered. A model on treads lets in navigation into places that individuals can’t safely seek advice from.

The device is designed to suit into current mining processes, so there’s no wish to redesign the way you pull ore out of the bottom or the rest — and although adjustments do wish to be made, they’re justified by way of larger potency, mentioned Activity.

Andrew Activity, founder & CEO of Plotlogic. Symbol Credit: Picture by way of Sarah Keayes/The Picture Pitch

“We see 3 kinds of advantages: monetary, environmental sustainability and protection,” he defined. “The operation can procedure extra ore and not more waste, making it extra winning. They may be able to be extra actual, leaving extra rocks in situ and now not expending gas and greenhouse gases transferring waste. And in spite of everything, it reduces human publicity hours within the mine.”

We will have moved previous the times of black lung however mining remains to be a basically difficult and perilous process. The fewer time employees are round heavy equipment, enclosed areas and air full of powdered rock, the easier. Having dependable and wealthy imagery may just additionally lend a hand herald independent mining faster somewhat than later, Activity recommended.

The $18 million A spherical was once led by way of Innovation Endeavors, with participation from BHP Ventures and Bentley iTwin Ventures — each project palms of primary mining teams — in addition to DCVC, Baidu Ventures and Grids Ventures. The plan is to make use of it to amplify industrial deployments and start running the world over.